SNS pneumatic GC Series FRL unit air source treatment combination air filter pressure regulator with lubricator

Technical Specification

|

Model |

GC 200 |

GC 300 |

GC 400 |

|

Module |

GF-200 |

GF-300 |

GF-400 |

|

GL-200 |

GL-300 |

GL-400 |

|

|

GR-200 |

GR-300 |

GR-400 |

|

|

Working Media |

Compressed Air |

||

|

Port Size |

G1/4 |

G3/8 |

G1/2 |

|

Pressure Range |

0.05-0.85MPa |

||

|

Max. Proof Pressure |

1.5MPa |

||

|

Water Cup Capacity |

10ml |

40ml |

80ml |

|

Oil Cup Capacity |

25ml |

75ml |

160ml |

|

Filter Precision |

40 μm(Normal)or 5 μm(Customized) |

||

|

Suggested Lubricating Oil |

Turbine No.1Oil (ISO VG32) |

||

|

Ambient Temperature |

-20~70℃ |

||

|

Material |

Body: Aluminum Alloy; Cup: PC |

||

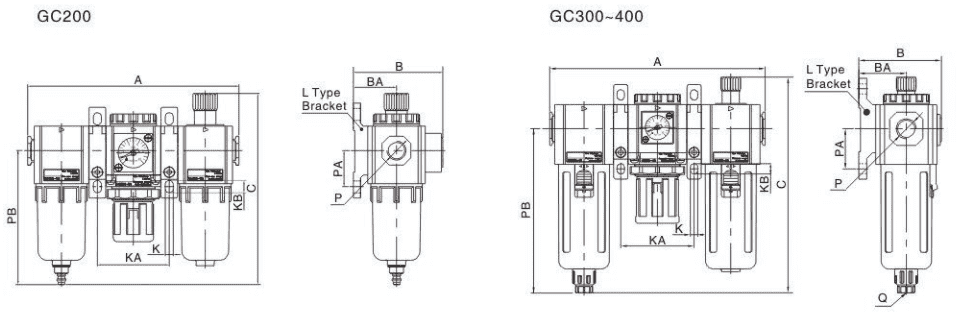

Dimension

|

Model |

A |

B |

BA |

C |

K |

KA |

KB |

P |

PA |

PB |

Q |

|

GC-200 |

147 |

62 |

30 |

133 |

5.5 |

50 |

8.4 |

G1/4 |

25 |

93 |

G1/8 |

|

GC-300 |

248 |

89 |

50 |

216 |

8.6 |

64 |

12 |

G3/8 |

40 |

166.5 |

G1/4 |

|

GC-400 |

248 |

89 |

50 |

216 |

8.6 |

84 |

12 |

G1/2 |

40 |

166.5 |

G1/4 |

Note : C value will be different with different draining module, more details please contact sales.

Write your message here and send it to us